Please carefully read our bent glass terms & conditions and sign at the bottom of the page.

Bent Glass Terms and Conditions

Custom Glass Industries fabricates and bends all curved glass to the outside (convex) dimensions. A guide to ensure correct measurements for your project can be found at cgifab.com/bent-glass-1. A minimum non-refundable deposit of 50% is due with the placement of order for production. A sign off of the following conditions is required before placement of order. All bent glass orders are Will Call only, unless shipping arrangements have been agreed upon.

BENT GLASS QUOTES

Bent glass quotes are based on the information given at the time of the quote. Custom Glass Industries Inc. is not responsible for any errors or omissions of the information. It is the customers’ responsibility to verify the accuracy of all quotes. Quote will be valid for only 30 days from the date the quote is returned to the customer.

Monolithic bent tempered glass is sold “AS IS” with “NO WARRANTY” and is not subject to return for surface imperfections. Bending and tempering glass does increase roll wave distortion, seeds, pits, scratches, and blemishes. Bent tempered laminated glass is subject to a 1 year limited warranty to protect against delamination. Inquire with your bent glass coordinator for more information.

BENT GLASS DIMENSIONAL TOLERANCES

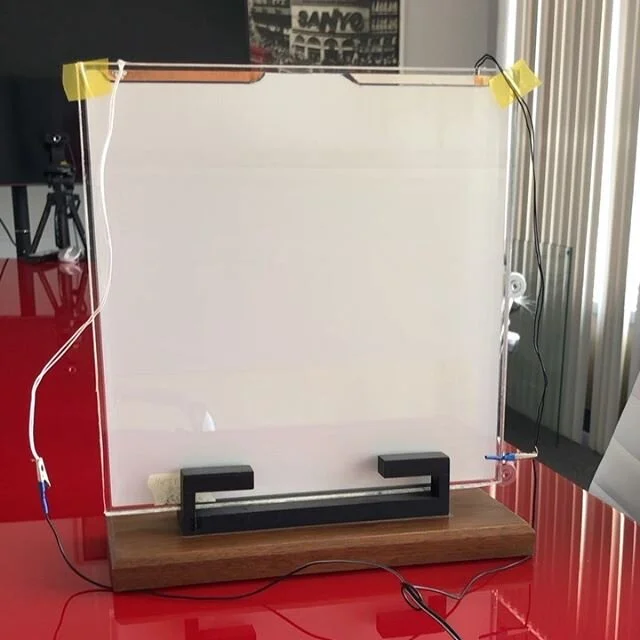

Custom Glass Industries follows ASTM Standard Specification for Bent Glass.Custom Glass Industries bends glass by heating and rolling the glass in one of our two tempering ovens. Glass is a visco-elastic material whose mechanical properties change rapidly when heated between 600° and 700°C becoming red hot and pliable.

Optical distortion fixes the restriction for most shaping. All curving demands precise control of stress levels to ensure the product meets environmental, robustness, regulatory, and optical requirements. A degree of distortion, both when looking through and in reflection, is inevitable in curved glass, particularly when viewing a moving object through the glass. Pock marks shall not exceed 1.6mm in the central portion of the glass and 2.4mm in the outer area. Ring marks shall not exceed 1.6mm in the central portion of the glass and 2.4mm in the outer area.

All curved glass should be site inspected from a minimum distance of 2 meters or 78 inches. After placing the glass in a vertical position, the viewer shall look through the specimen using daylight without direct sunlight or using a background light suitable for observing the blemishes. It should also be noted that curved glass will split direct sunlight into striped shadow. Some variation in edgework may be discernible on exposed edges where different machine or hand forming is required for manufacturing. Such variation will be kept to a minimum.

Bent tempered laminated glass will display more distortion than monolithic bent tempered glass, since the innerlayer acts as a mirror for the distortion of the surrounding pieces. The distortion for laminated and monolithic bent tempered glass may increase as the radius decreases.

Up to the last 5% of each vertical edge may straighten out depending on where the glass hits the rollers in our machine. This may fluctuate based on the arc of the glass. The straight edges may change the desired cord, arc, and radius.

SMARTMEASURE (where applicable)

SmartMeasure estimate is not a guarantee that we can fabricate the glass. If it is identified on site that Custom Industries cannot fabricate the glass, the customer will receive a refund minus $450 for processing, time, and travel. By agreeing to SmartMeasure, you agree to the CGI Bent Glass Terms & Conditions.

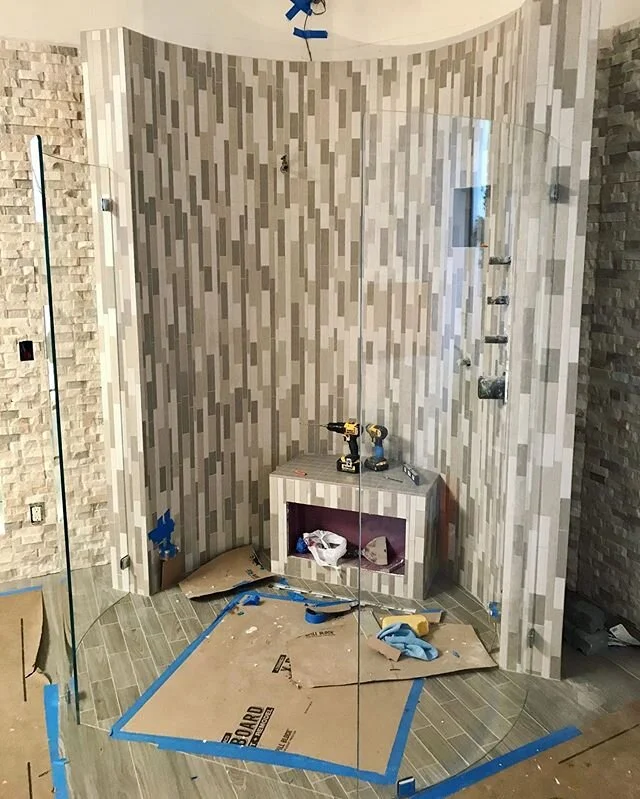

GLAZING OF BENT GLASS

Standard glazing techniques for flat glass also apply to curved glass with added consideration of the following:

Glass radius and rebate radius are rarely exactly the same. Additionally radius at head may differ from that at the sill. Rebate needs to be of sufficient size to accommodate all variances. Where variances occur wet seal is recommended.

Attention needs to be paid to the frame that the curved glass is being glazed into. In particular attention to the blocking of the frame into the sub-sill in the center of the bow, as this area may droop over time if not blocked sufficiently.

Setting blocks and distance pieces: Same as for flat glass with the exception that a central setting block/s may be required to avoid tipping, depending on the radius.

Curved glass vacuum lifters are recommended for assisting with moving the glass into position. Note that flat glass vacuum lifters are not recommended for use on curved glass as they may lose their vacuum suddenly.

COURTESY STORAGE FEE

We offer a 5 business day extension from your original Will Call date as stated on your Order Confirmation. After this date Custom Glass Industries is no longer liable for the condition in which you receive your glass.

A storage fee of $25 per day for orders less than 5 pieces and $50 per day for orders more than 5 pieces will be applied to your balance. If your glass is not picked up within 10 business days of your order confirmation Will Call date, your storage fee will be raised to $50 per day for orders less than 5 pieces and $75 per day for orders more than 5 pieces. Glass not picked up within 20 business days of Will Call date will be disposed.

All applicable fees, in addition to your balance, must be paid before your order is released.