Curved Glass Dimensional Tolerances

Custom Glass Industries follows ASTM Standard Specification for Bent Glass.

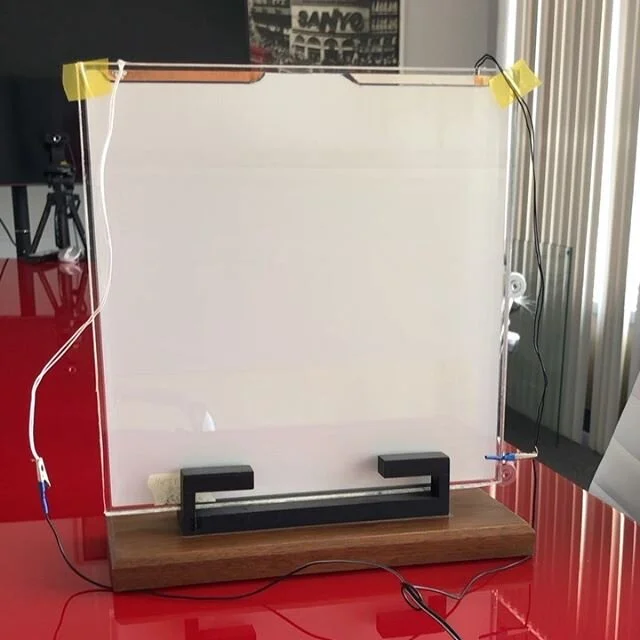

Custom Glass Industries bends glass by heating and rolling the glass in one of our two tempering ovens. Glass is a visco-elastic material whose mechanical properties change rapidly when heated between 600° and 700°C becoming red hot and pliable. (The science of glass bending uses this plastic phase to produce shapes which are both complex yet free from wrinkles and other optical aberrations starting from flat float glass.)

Optical distortion fixes the restriction for most shaping. All curving demands precise control of stress levels to ensure the product meets environmental, robustness, regulatory, and optical requirements. A degree of distortion, both when looking through and in reflection, is inevitable in curved glass, particularly when viewing a moving object through the glass. Pock marks shall not exceed 1.6mm in the central portion of the glass and 2.4mm in the outer area. Ring marks shall not exceed 1.6mm in the central portion of the glass and 2.4mm in the outer area.

All curved glass should be site inspected from a minimum distance of 2m or 78 inches. Place specimen in a vertical position; the viewer shall look through the specimen using daylight without direct sunlight or using a background light suitable for observing the blemishes. It should also be noted that curved glass will split direct sunlight into striped shadow. Some variation in edgework may be discernible on exposed edges where different machine or hand forming is required for manufacturing. Such variation will be kept to a minimum.

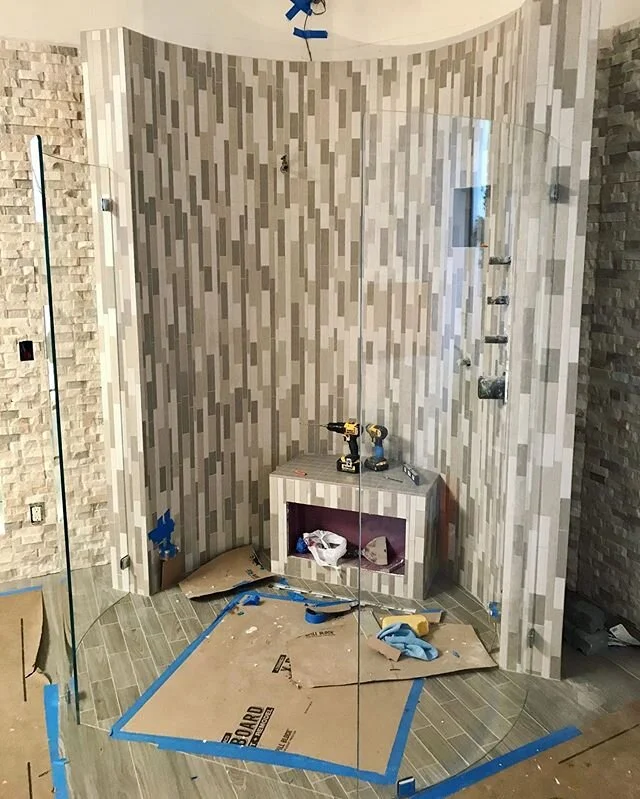

Glazing of Curved Glass

Standard glazing techniques for flat glass also apply to curved glass with added consideration of the following:

• Glass radius and rebate radius are rarely exactly the same. Additionally radius at head may differ from that at the sill. Rebate needs to be of sufficient size to accommodate all variances. Where variances occur wet seal is recommended.

• Attention needs to be paid to the frame that the curved glass is being glazed into. In particular attention to the blocking of the frame into the sub-sill in the center of the bow, as this area may droop over time if not blocked sufficiently.

• Setting blocks and distance pieces: Same as for flat glass with the exception that a central setting block/s may be required to avoid tipping, depending on the radius.

• Curved glass vacuum lifters are recommended for assisting with moving the glass into position. Note that flat glass vacuum lifters are not recommended for use on curved glass as they may lose their vacuum suddenly.